Pricing & Ordering

|

|

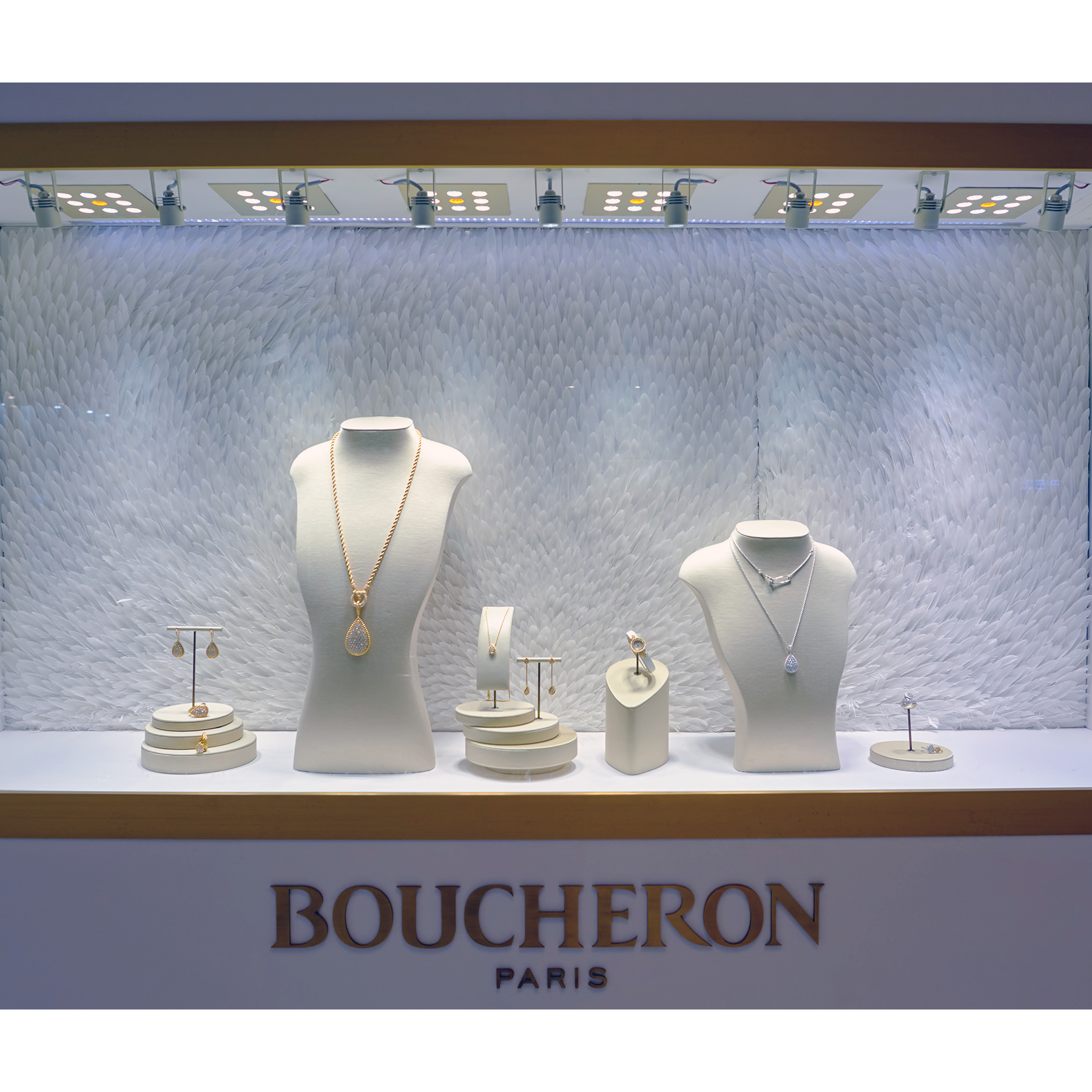

What is Museum Glass? Why not just use regular glass? It’s often used in museum displays, retail storefronts, swanky steakhouses, and multi-million dollar art.

For pricing & ordering, you can use the price calculator at the top of this page or contact us for a custom quote. We accept CAD drawings, PDFs and JPG images of special shapes. Shoot us an email with what you need and we will provide a fast quote which includes all of your specifications.

Museum Glass eliminates the sight inhibiting reflections and glare that are commonly observed with regular, every day glass.

- 1% luminous reflectance

- Best possible color stability

- Durable coating

- 99% UV protection

- Temperable

- Clear and neutral

- Weatherproof

- Easy to clean

- Low iron substrate

- Increases natural daylight in rooms

- Scratch resistant

- Best possible color stability with change in viewing angle

- Fast Shipping – We’re standing by to cut and ship your order immediately.

- UV Protection – Protects people and valuable items from harmful UV light.

- Low Iron Substrate – Eliminates the green tint normally seen in glass.

- Optical Grade – Dielectric technology provides high level of light transmission

- Expert Packaging – Carefully packed and fully insured to protect your investment.

- Guaranteed Quality – Backed by our industry-leading return policy.

- Sanded Edges – The edges of the glass is carefully sanded for your protection.

- Durable Coating – Clean with standard glass cleaner and paper towels.

- Worldwide Service – We carefully package and ship the glass from our factory in the USA.

Imagine a world without Museum Glass… Your glasses would have back-glare (light hits the back of the lenses, right into your eye). Customers couldn’t see your display on the outside of your store, leading towards a lack of business. There wouldn’t be a point in picture frames or museum exhibits when you can’t what’s on the other side because of the high reflection.

- Science & engineering

- Display cases

- Recording studios

- Observation windows

- Protect valuable art

- VIP stadium seating

- Museum exhibits

- Upscale architecture

- Luxury retail & restaurants

- Zoo & aquarium exhibits

- Retail storefronts

- Hospital windows

AR coatings, also known as anti-reflective coatings, are dielectric nanotechnology and are created by dipping low iron glass into special metal oxide solutions. The glass is then heated to 500 degrees Celsius to create oxidic layers that eliminate reflections.

The result of this process has an extremely high clarity, which can be used in a wide variety of applications, especially in bright areas, where reflection would prevent visibility.

Museum Glass has a hard coating that withstands tempering to enhance safety and security. This makes it perfect for upscale applications where the public or children may be close to the glass. When people are pressing up against the glass, for example, in outdoor applications such as zoos, this is a crucial feature to ensure the glass is strong enough to keep people safe. Because it’s anti-reflective, viewers can maintain more of a distance from the exhibits to see clearly, so they can stand back from the glass. It’s the high light transmission combined with the reduced reflection that makes the Museum Glass a truly magical piece of glass. This combination will eliminate the sight inhibiting reflections from the glass, allowing the potential customer to see the showcased item with crystal clear clarity.

Museum Glass is a critical aspect for many displays, such as jewelry cases, storefronts, and aquariums. Why? Say you go into a nice jewelry store, you want the perfect ring, the one. The jewelry store is super nice inside, you can tell it’s expensive. As you are looking for the perfect ring, and you can’t see through the glass. Instead of the immaculate rings, all you can see are frustrating reflections from the light above the display, or even your own reflection. The reflection inhibits your sight, blocking all of the great options. This can be a huge problem for the seller and can even result in losing business. It goes the same for store fronts and aquariums.

One of the most famous paintings, the Mona Lisa painted by Leonardo da Vinci, has completely changed over the years. It has not only faded, but has shrunk and even gained a yellow layer over it. Scientists have proven that this has resulted from flash photography, UV radiation, and just ageing. Scientists removed age spots in the 1950s, very carefully. Today, the Mona Lisa is in an air-conditioned frame, no flash photography is allowed, and people are required to stand back from it.

Museum Glass simultaneously blocks 99% of harmful UV rays, while offering high transmission through the glass. That makes it perfect for protecting expensive art pieces and keeping people safe behind it.

UV radiation is harmful rays that can hurt paintings and drawings. Too much exposure of UV Radiation can damage works of art overtime. This will cause fading, cracking, distortion, and lifts the surface of the art. Using Museum Glass is only the first step for Museum Exhibits. Museum directors invest a ton of money and time in making sure the art is safe. They have to keep the humidity to a low, using a UV meter, and proper lighting. Most Museums block all harmful UV radiation from coming into the building, so it is less to worry about. Museum Glass is MUST have for museums, as you can see.

Museum Glass comes readily prepared to handle all weather conditions with its weather resistant coating.

Our orders are typically cut and shipped the day of purchase.

This glass protects against UV radiation, making art behind the glass, last much longer as well as prevents from fading.

Museum Glass has a low iron substrate which eliminates the greenish tint that is often observed with normal glass. Museum glass is clear and color neutral.

Yes, you can! Simply contact us and we will send you a quote right away.

All of our glass is shipped with sanded edges to ensure safety for our clients. Polished edges are created using a fine belt until the edges are smooth.

Of course, that’s our specialty! Simply email us an image of the shape that you desire, along with your specific measurements, and we will send you a quote right away!

It’s very unlikely that our mirrors will break in transit. Our mirrors are fully insured and packaged in custom boxes and wrapped in strong, flexible packing materials to ensure that they’re well-protected during transit. If they should arrive broken, send us a picture of the broken glass and the outside of the box, and we will send replacements right away.

We are standing by to cut and package your glass immediately. Untempered glass is typically shipped within 1 day, tempered glass takes about 1 week.